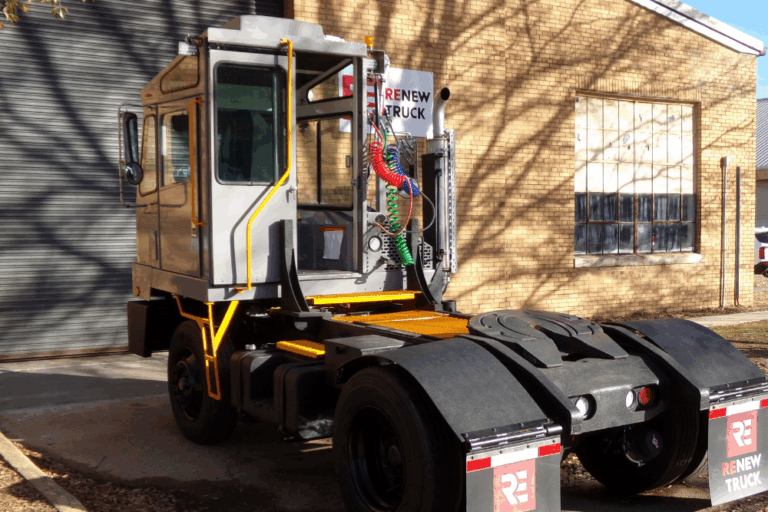

The holiday season brings a massive surge in shipping and distribution activity, and your yard truck fleet needs to be ready for the challenge. Preparing your spotter trucks well in advance of peak demand can prevent costly downtime, keep your operations running smoothly, and ensure you’re not scrambling for emergency repairs when every hour counts. At Renew Truck in New Boston, Texas, we help fleet managers across the country get their yard trucks in peak condition before the holiday rush begins.

Whether you’re managing a rental fleet, running a distribution center, or operating a busy manufacturing facility, the increased demand from November through January puts serious strain on your equipment. Pre-season inspections, targeted repairs, and strategic planning can mean the difference between a profitable holiday season and operational chaos. Let’s walk through the essential steps to prepare your yard truck fleet for the busiest time of year.

Why Holiday Planning Matters for Your Yard Truck Fleet

Holiday demand isn’t just a slight uptick in activity. It’s a complete transformation of your operation. Distribution centers that normally move 500 trailers a day might suddenly handle 800 or more. Rental companies see their entire fleet in constant use. Manufacturing facilities run extended shifts to keep up with orders.

Your yard trucks are the backbone of this operation. When a spotter truck goes down during peak season, it creates a bottleneck that slows your entire operation. Drivers wait for available trucks. Trailers sit unloaded. Shipments get delayed. Revenue takes a hit. Planning ahead protects your bottom line and keeps your operation running at full capacity when it matters most.

Start with a Comprehensive Fleet Assessment

Before the holiday rush hits, you need to know exactly where your fleet stands. This means going beyond your regular maintenance schedule to identify potential weak points that could fail under increased demand.

Digital Inspections Reveal Hidden Issues

A thorough digital inspection pulls codes and identifies problems that might not be obvious during normal operation. At Renew Truck, we pull codes and take photos of problem areas, then email you detailed explanations of what needs attention and why. This gives you a clear picture of your fleet’s condition and helps you prioritize repairs.

Focus on High-Wear Components

Certain parts of your yard truck take the most punishment during heavy use. Pay special attention to:

- Drivetrain components, including engines and transmissions, that will work harder during extended shifts

- Pins and bushings that wear down faster with increased cycles

- Hydraulic systems that control your fifth wheel and lifting mechanisms

- Electrical systems, including gauges, lights, and wiring, that keep your trucks safe and compliant

- Tires that need adequate tread for constant yard movement

Document Your Findings

Create a detailed record of each truck’s condition. Note the hours on each unit, any recurring issues, and maintenance history. This documentation helps you make informed decisions about which trucks need immediate attention and which ones can wait until after the season.

Prioritize Critical Repairs and Preventative Maintenance

Once you’ve assessed your fleet, it’s time to make strategic decisions about repairs. Not every issue requires immediate attention, but some problems will only get worse under holiday stress.

Don't Overlook Routine Maintenance

Regularly scheduled preventative maintenance becomes even more critical before holiday demand. Fresh fluids, clean filters, and properly maintained systems reduce the risk of breakdowns. If you’ve been putting off routine service, catch up now before the rush begins.

Beyond our specialized remanufacturing services, we also provide regular scheduled preventative maintenance and inspections to help you keep your entire fleet in top condition year-round.

Consider Strategic Rebuilds

If you have trucks approaching the end of their useful life, consider a full remanufacture before the holidays. Our frame-off restorations completely rebuild your truck from the tires up, giving you essentially a new truck in 60 to 90 days instead of waiting 18 months or more for a new unit.

This approach saves you money compared to buying new while ensuring you have reliable equipment when demand peaks. All drivetrain components are remanufactured to military specifications using ISO 9001-2015 quality standards, giving you confidence in the work.

Ready to get your yard truck fleet holiday-ready? Contact our team at Renew Truck today. We’re located at 150 Service Street, New Boston, TX 75570, or call us at 903-231-9002 to discuss your fleet’s needs and schedule inspections.

Plan for Backup Capacity and Flexibility

Even with perfect maintenance, increased demand might stretch your fleet beyond its normal capacity. Smart planning includes having backup options ready.

Schedule Repairs Strategically

You can’t take your entire fleet offline at once for maintenance. Create a rolling schedule that addresses the most critical units first while keeping enough trucks operational to handle current demand.

Cross-Train Your Team

Make sure multiple people know how to operate and perform basic troubleshooting on your yard trucks. When you’re running extended shifts during the holidays, you need flexibility in your workforce. Driver familiarity with the equipment reduces mistakes and helps identify problems early.

Why Choose Renew Truck for Your Holiday Fleet Preparation

When you’re preparing for the busiest season of the year, you need a partner who understands the stakes. Here’s what sets us apart:

- ASE Certified Mechanics with expertise in spotter truck systems and components

- Fast turnaround times of 60 to 90 days for complete remanufactures, getting your trucks back in service quickly

- Military-grade quality standards with all drivetrain components meeting ISO 9001-2015 specifications

- Comprehensive warranty protection, including 2,000-hour, one-year coverage on drivetrain components

- Nationwide service accepting trucks from across the United States and Canada

- Collaborative approach that customizes our work to your specific operational needs

- Full-service capabilities from routine maintenance to complete frame-off restorations

We service all major brands, including Kalmar Ottawa, Capacity, TICO, and Terberg yard trucks, and we’re experienced with the Cummins engines that power most spotter truck fleets.

Common Holiday Season Challenges for Yard Trucks

Understanding the specific stresses your equipment will face helps you prepare more effectively. Holiday operations differ from normal activity in several key ways.

Extended Operating Hours

Instead of single shifts, you might run two or three shifts daily. This means your trucks get far less rest time between uses. Components that normally cool down overnight stay hot for extended periods, accelerating wear on engines, transmissions, and hydraulic systems.

Increased Cycle Counts

A yard truck might make 200 trailer moves on a normal day. During the holidays, that number could jump to 300 or 400. Every coupling, turn, acceleration, and brake application adds up. Wear points like pins and bushings that might last months under normal use can fail within weeks under holiday stress.

Inexperienced Operators

Peak season often means temporary workers or less experienced operators handling your equipment. They might be less familiar with proper operation, potentially causing more wear or missing early warning signs of problems. Having equipment in top condition helps compensate for this reality.

Weather Challenges

The holiday season coincides with winter in much of the country. Cold temperatures affect diesel engines, batteries, and hydraulics. Wet or icy conditions in your yard add stress to tires and braking systems. Preparing for these environmental factors protects your fleet.

The Real Cost of Holiday Downtime

When a yard truck breaks down during peak season, the financial impact goes far beyond the repair cost.

Distribution Center Impact:

- Large facilities can process tens of thousands of dollars in goods per hour

- Even a 20% operational slowdown over several hours can result in significant delayed revenue

- Factor in late shipping penalties, worker overtime, and emergency repair premiums

- A single breakdown during peak season can cost tens of thousands of dollars

Rental Company Impact:

- Yard trucks generating daily rental income lose every dollar while sitting idle

- Emergency repairs during peak season command premium rates

- Week-long downtime translates to thousands in unrecoverable lost revenue

The Bottom Line: Preventative preparation is always cheaper than emergency repairs. Strategic pre-season maintenance protects your operation from these avoidable costs when you can least afford them.

FAQs About Yard Truck Holiday Maintenance

How far in advance should I start preparing my yard truck fleet for the holidays?

The earlier you start preparing your yard truck fleet, the better. Comprehensive inspections and routine maintenance can be completed in days or weeks, while major repairs may take several weeks, and complete remanufactures require 60 to 90 days. Starting early gives you the flexibility to address issues properly without rushing through critical repairs or facing emergency situations during peak demand.

What are the most common yard truck failures during holiday demand?

The most common failures during holiday demand are drivetrain components, hydraulic systems, and high-wear items like pins and bushings that fail under increased cycle counts. Extended operating hours and reduced rest time between uses accelerate wear on these critical systems.

Should I repair or replace aging yard trucks before the holidays?

If your truck requires frequent repairs or is approaching the end of its life, a complete remanufacture offers better value than buying new equipment. Get a fully rebuilt truck in 60-90 days with warranty protection.

Can preventative maintenance really prevent breakdowns during peak season?

Yes, preventative maintenance significantly reduces breakdown risk by identifying and addressing potential failures before they occur. Regular maintenance catches problems early when they’re cheaper and easier to fix, protecting you from costly emergency repairs during the worst possible time.

Schedule Your Yard Truck Holiday Maintenance in New Boston, TX Today

Don’t wait until the holiday rush is here to discover your yard truck fleet isn’t ready. The time to prepare is now, before increased demand exposes weak points in your equipment. Whether you need routine maintenance, targeted repairs, or complete remanufactures, Renew Truck has the expertise and capacity to get your fleet ready for the busiest season of the year.

Visit us at Renew Truck, 150 Service Street, New Boston, TX 75570, or call us at 903-231-9002 to schedule your fleet assessment. We service trucks nationwide and work with your timeline to ensure your equipment is ready when holiday demand arrives.

Let us help you prepare for a successful, profitable holiday season.